To meet market demands, production involves the meeting of speed, accuracy, and flexibility, while also making sure there is an optimum and efficient workflow. On the other hand, flexo printers are some of the best printers to use for packinging due to their unrivaled and specialized designs. Many industries ponder the question of how these flexo printers streamline the supply chain and production of win distributions. This article aims to clarify how flexo printers add value production processes and how they yield a greater outcome for the finished goods in a project.

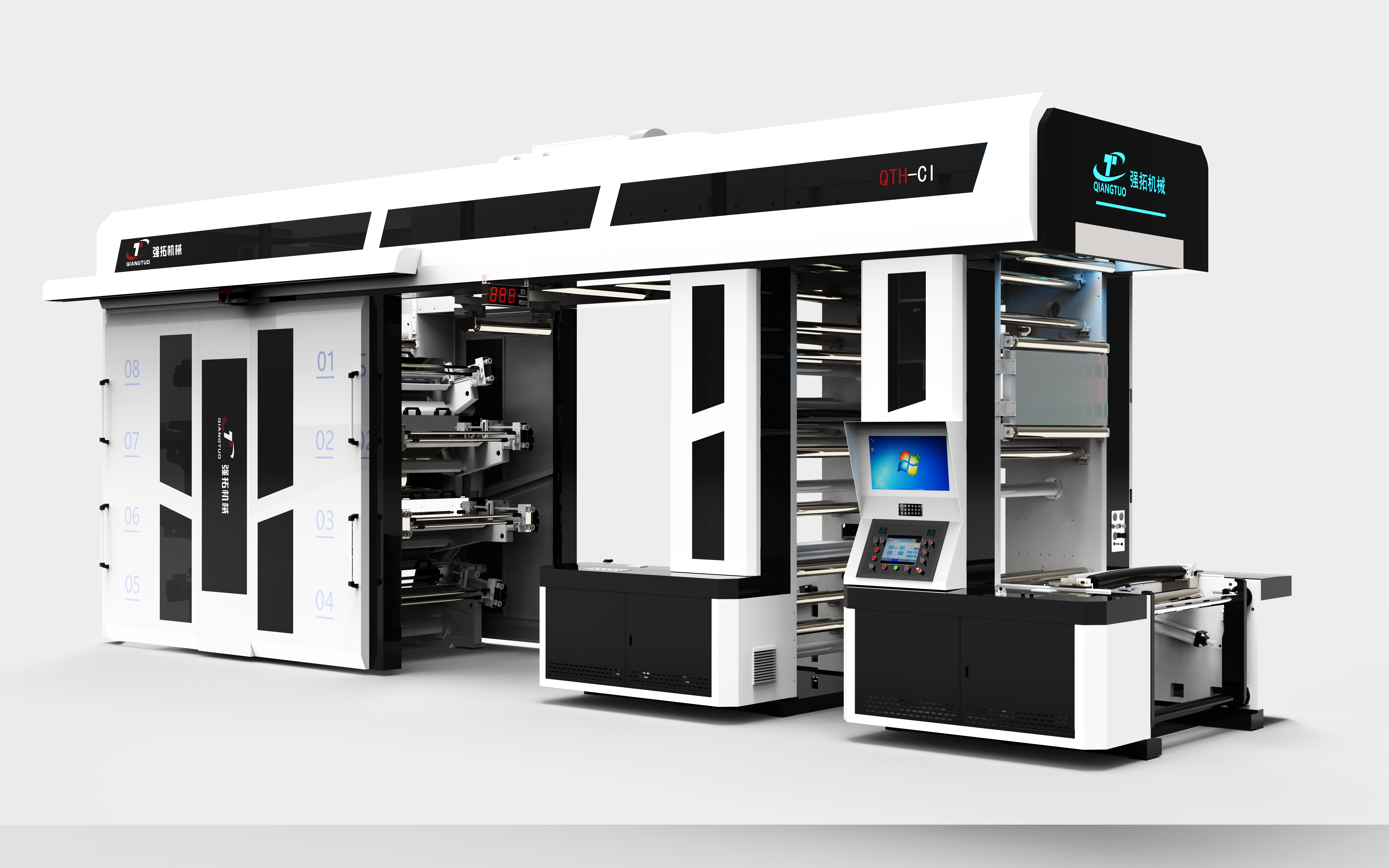

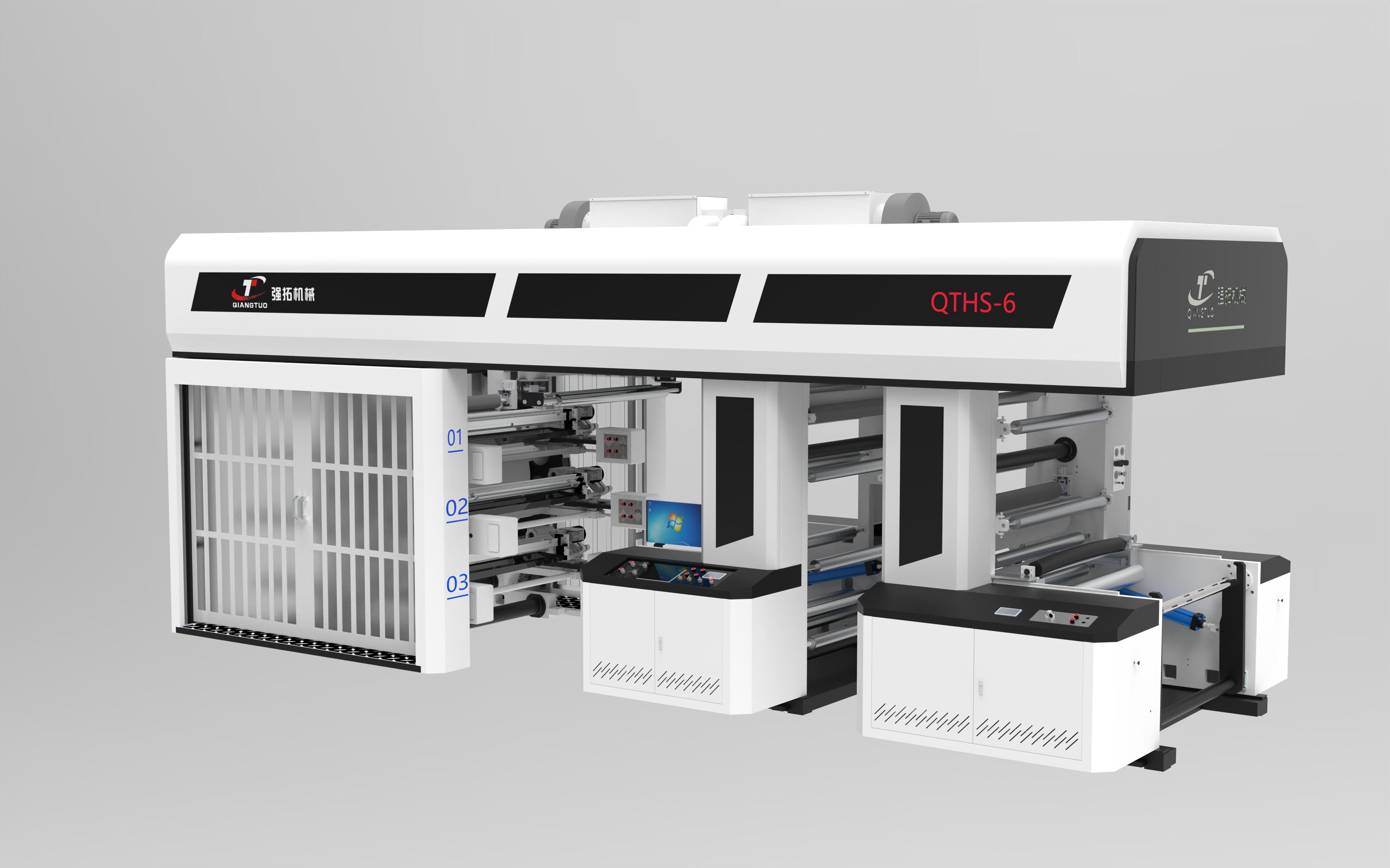

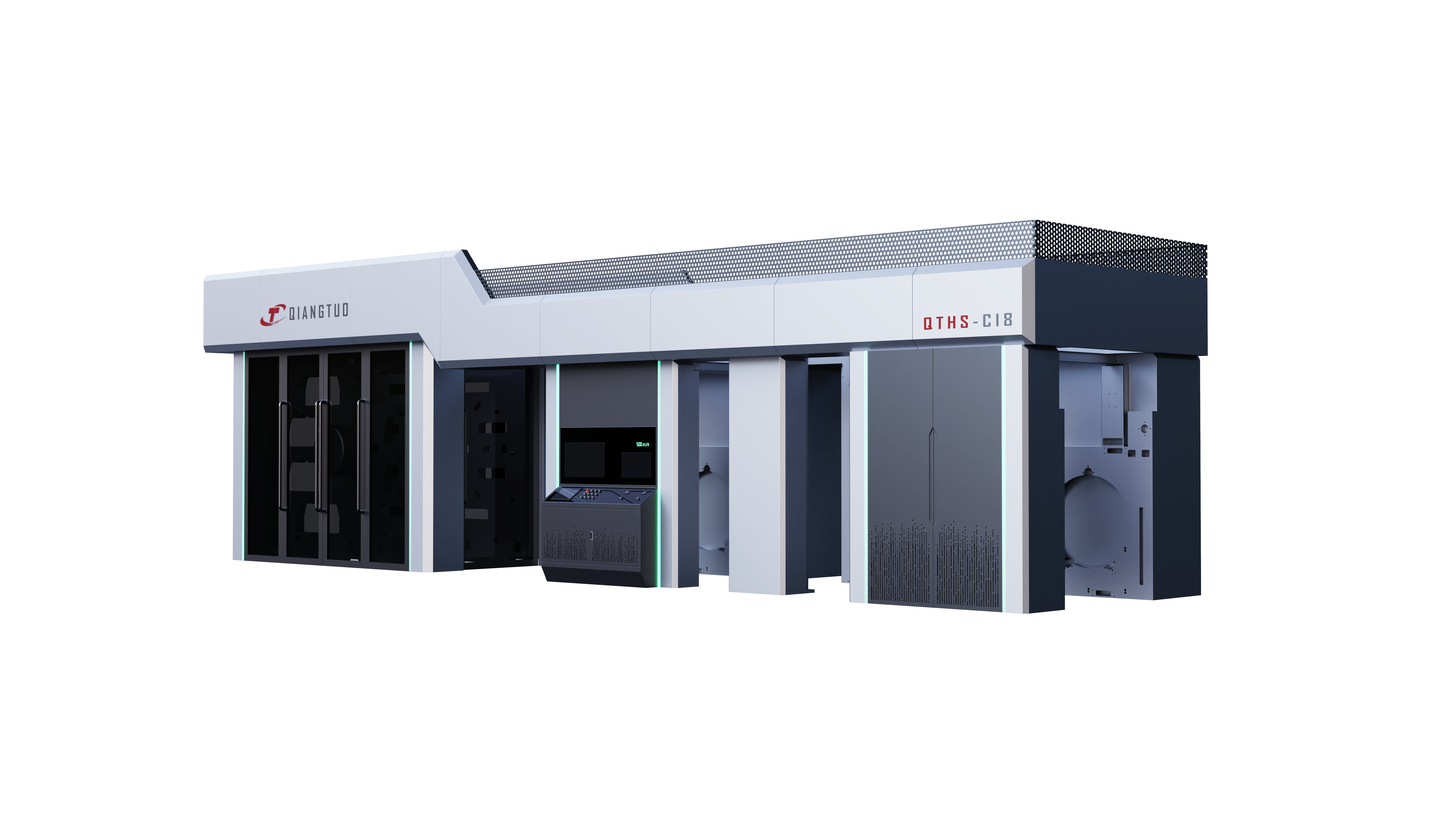

Like other flexo printers, speed is advanced and performance is optimal. The flexo printer has some advantages over other printers in class due to the increased volumes of materials they can handle at a time. Moreover, they are some of the few printers who print at over a hundred meters in speed with films, paper, and corrugated boxes. The production of these materials adds value to the time and lowers the costs of flexo printers.

Flexo printers exhibit flexibility and the ability to adapt to different materials. This is a plus because other materials are added to the production line.

Different packaging substrates such as paper, plastics, non woven fabrics, and metalized films are all materials which packaging manufacturers might come across. Unlike specialized printers who only deal with one material, flexo machines are capable of switching materials with little modification. For example, one flexo machine is able to print on ‘food packging’ plastic bags and ‘cosmetic’ paper boxes and are able to do so without extensive re-tooling. The machine works on both materials and this form versatility means there is no need to purchase multiple printers. This form versatility also prevents loss of space in the manufacturing plant, mitigates the loss of time on multiple pieces of equipment, and reduces time on equipment changes.

Flexo works to improve the efficiency of the packaging process, and changes the negative perception many might have of the long time spent on setup and changes with one where time is spent efficiently. For example, many flexo machines have user friendly systems which reduce the time spent on changing the boxes to be printed to ‘food packaging’ boxes. Other models come with preset ink alignment and cutting systems and tailored print remote retrievers. This means that many manufacturers are no longer confined to only large volumes of stock because they are able to satisfy multiple orders of smaller quantities.

Shifts in employment structure allow companies even more agility in responding to requests from customers and changes in the market.

In packaging, quality control is critical since the packet can get damaged or defected leading to scrapped resources and the entire procedure getting redone, which is inefficient. Flexographic machines are able to control the optimization of ink and the pressure in a sophisticated manner in order to preserve quality. In additional modern flexographic machinery the advanced adhering techniques to the flexographic printing plates, which are polymerized, and to the superlative systems controlling drying avoid even the highest printing speeds. This means less time and material in saving the batch from the defective logo requirements. This is especially relevant when several thousands of boxes need to have the exact same logo printed on them. Flexographic machines reliably meets their packaging needs.

Material costs & losing money due to inefficient techniques are major challenges in packaging production. Defective materials are usually discarded but with flexographic printing machinery materials used are aligned in order to diminish wastage.

Flexography also comes with some material savings features. These include edge printing and minimizing space between printed graphics. Reduced waste is also good from a cost standpoint and increases efficiency from a resource utilization perspective. This increases the sustainability and profitability of the entire package.

Flexo printing machines, like other machines in modern production, have to be automated. This also increases efficiency in the printing machines. These flexo machines can be linked to other machines involved in the packing process to create a seamless workflow. For instance, a printed roll of plastic film can be directly fed to a cutting machine for bags. In this scenario, there is no need for the transport of materials between different stations. Automation in this instance reduces the labor cost, the cost as well as the production cycle.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16