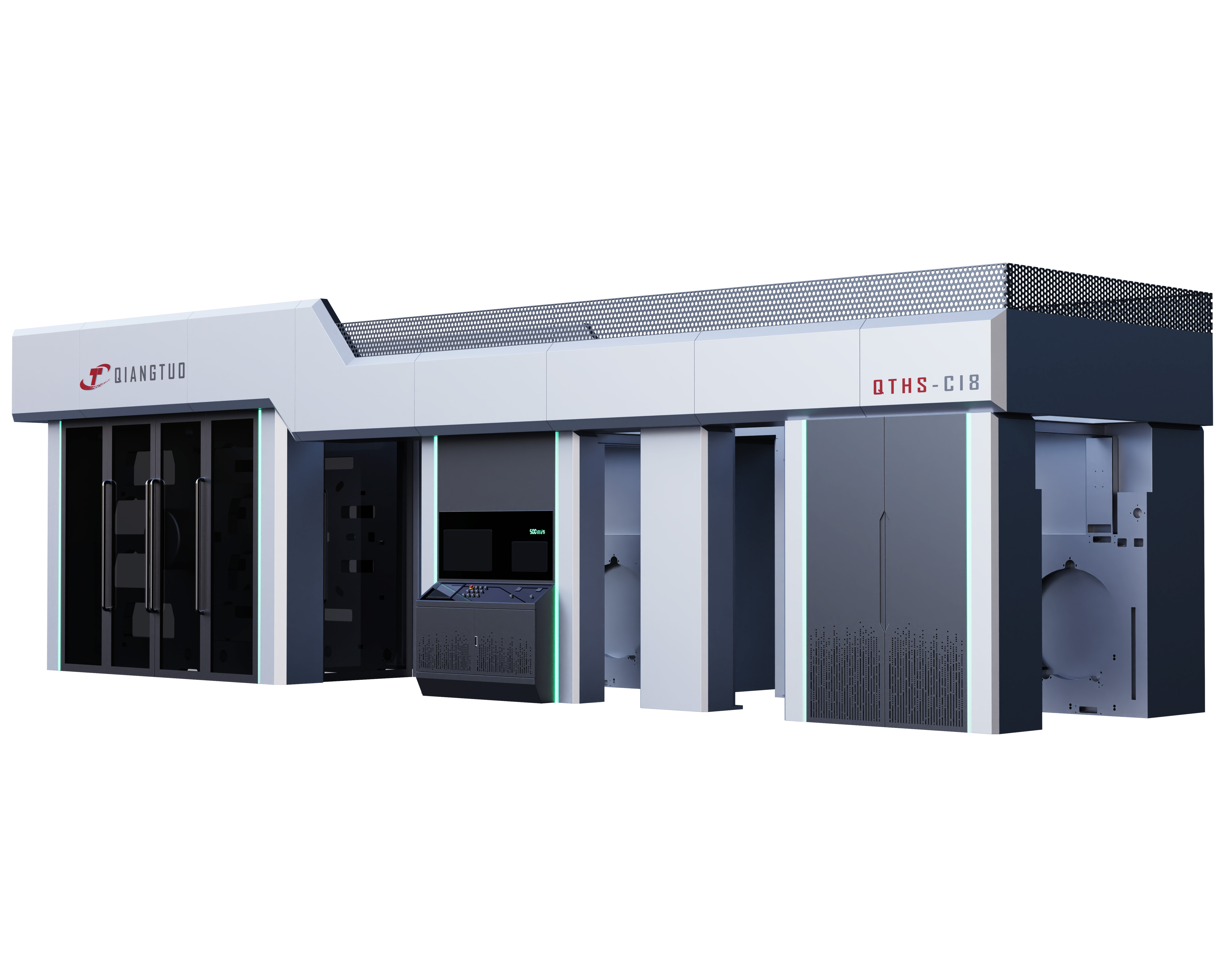

When it comes to the modern printing industry, color registration precision determines the clarity, consistency, and competitive advantage of a given product. In printing flexible packaging, paper, and non-wovens, a color registration defect leads to product loss and customer returns. How is it then that Qiangtuo Printing Machinery, a flexographic printing machine manufacturer, was able to launch a full-servo flexo printing machine that excels in color registration control? After 20 years of operating in the industry, many clients have similar inquiries. In this text, we will review a number of technical and design aspects to analyze the control of color registration precision provided by this machine.

The full-servo drive system is the core technology providing full-color registration of Qiangtuo full-servo flexo printing machine. Unlike conventional mechanical drive systems that incorporate gears and shafts, and, therefore, are subject to wear and transmission errors, the full-servo systems utilize independent servo motors controlling each printing unit, which are the unwinding, printing, and rewinding modules. Each servo motor possesses an operational error of less than 0.01mm, which permits the real-time adjustment of the speed and position of each printing unit. In situations where the machine changes to print different substrates, like paper, non-woven, and plastic, or adjusts the printing speed (for CI models, up to 260m/min), the servo system color registration addresses several variances without speed changes or material stretches to eliminate the faults of color misalignment. This independent and precise control of each color layer creates the extensive base needed for high color registration accuracy.

One of the most sophisticated modern features of Qiangtuo full-servo flexo printing machines is the use of advanced sensors and automatic color registration error detection and correction in real-time. High-precision color mark sensors are mounted over the printing platform and continuously monitor the location of pre-printed color marks on the material. Once the sensor detects a deviation, such as in the Y-axis, the sensor immediately sends information to the control system of the machine. After the control system receives the information, the control system determines the needed adjustments based on the deviation value, the current printing speed, and the characteristics of the material. The control system then commands the servo motor to make the needed adjustments to the printing plate roller or the guide mechanism of the material. For example, when printing on stretchable nonwoven fabrics, if the material is moved during the transmission, the automatic correction system is able to make adjustments in less than 0.1 seconds to make sure the next color layers are aligned over the previously printed color layers. The system eliminates color registration deviation errors caused by material stretch, mechanical vibrations, or temperature changes.

The design of the Printing Unit Structures directly correlates to the stability of the color registration. The full servo flexo printing machines by Qiangtuo have multiple optimisations for this. Firstly, the printing unit adopts the 'X-type' structure, just like the heightened flexo printing technologies. This structure design ensures stable pressure from the printing plate roller, anilox roller and impression roller across the printing cycle. This means even for changing the printing plates to ones of a smaller/larger size, or even changing the print repeat lengths from 350-1000mm, there is never a need to reset the printing pressure. This avoids color registration drifting which is a common issue when there is an imbalance in printing pressure. Secondly, anox rollers utilize a laser engraving technology with the mesh depth and sizes being uniform to ensure uniform and accurate transfer of ink. For example, when printing fine patterns, especially on paper materials, a high-line anilox roller with up to 800 lines/inch is utilized. This balances ink control to avoid color bleeding or overlay. The pressure control and uniform transfer of ink ensures registration of the colors is highly accurate.

Precision and material stability are essential to minimizing color registration issues during printing. When it comes to material prep, Qiangtuo's full-servo flexo printing machine has been designed with a top-of-the-line processing module that flattens and dusts the materials. This ensures that during the print run, any potential factors that could cause deviations during material processing are eliminated, such as wrinkles, static, or surface dust. For tension control, the machine is equipped with a closed-loop tension control that tracks the tension of the material during unwinding, printing, and rewinding. For example, when printing on a thick woven bag material that has high tension requirements, or during printing on a thin plastic film that is easily overstretched, the system automatically modifies the tension throughout the print run to prevent color registration errors. This all-link tension control ensures that the material remains stable throughout the print run, laying a dependable foundation for accurate color overlay.

To ensure color registration accuracy on its full-servo flexo printing machines, Qiangtuo follows a strict set of calibration and quality control procedures. During production, only top tier suppliers are used for critical parts such as printing rollers, sensors, and servo motors and they are all subjected to thorough pre-production testing. In the final stage of production, every flexo printing machine that has been fully outfitted with servo motors is tested in an operational capacity for 72 hours without interruption, printing a monitored set of color designs on a variety of materials (paper, plastics, non-woven fabrics) at differing operational speeds. Any member of the quality control team that is present on the shop floor is equipped with tools to measure color registration error down to a 0.05 mm accuracy level. Technicians then adjust servo parameters and sensor adjust sensitivities if a color registration error deviation at the 0.05 mm level is detected. This results in machines with an overall 0.05 mm deviation threshold for color registration providing control to the end user at an operational level to be confident in the performance accuracy of their machine.

As an example of adaptability, printing materials have their own individual physical characteristics (e.g. stretchability, thickness, surface smoothness) and how these affect color registration, and how Qiangtuo's full-servo flexo printing machine addresses these challenges differently. For paper printing (low stretchability), the machine adapts by using a rigid material guide mechanism in order to keep stable transmission; for non-woven printing (fluffing prone), a special anti-static guide roller is added to help prevent material offset due to static attraction; for plastic printing (high stretchability), the servo system slows stretch during the early transmission phase by using a "slow start" setting. In other ways, the machine is able to customize printing unit configuration (2-8 colors) and the dimensions of plate roller so clientele may modify the device to fit their product specifications. Such an adaptive system is what allows the full-servo flexo printing machine to achieve outstanding color registration accuracy across a myriad of situations.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16