A flexo printing machine is essential in the printing of packaging, labels, and flexible materials. It prints from various substrates including plastic films, paper and non woven fabrics using flexible relief plates. When buying a flexo printing machine, one has to find a suitable balance between efficiency and precision. A machine’s efficiency is critical to meet production deadlines. Precision on the other hand is essential to ensure that printed materials meets quality standards. With the number of different models and configurations of flexo printing machines, buyers often have a hard time figuring out which model suits them best. Knowing the factors that best evaluate the efficiency and precision in a flexo printing machine is critical for making a business-friendly purchase.

Flexo printing machine efficiency will have an impact on production capacity and cost effectiveness. To start, printing speed is a key indicator of efficiency. A quality flexo printing machine will have various adjustable speed ranges for different substrates and printing jobs. For instance, a machine can be 300 meters per minute for simple label printing while being stable. If a machine is slow, that will not only extend production time, but also increase labor and energy costs. Lastly, to complete the overall efficiency equation, setup time also has to be considered.

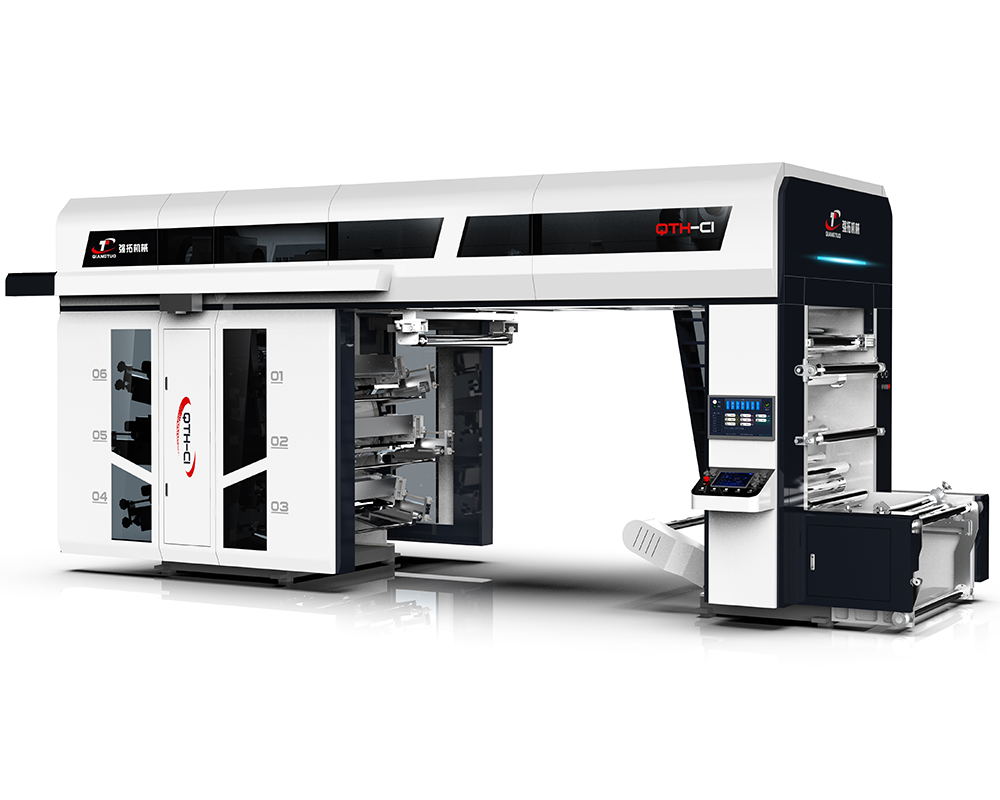

A flexo printing machine with quick change options for plates, anilox rollers, and substrates can minimize setup time from hours to mere minutes! This is a game changer for small batch and custom print jobs since these frequent setup changes can be time consuming. Third, operational reliability minimizes downtime. A flexo printing machine designed to reduce the risk of breakdowns with reliable components and easy maintenance ensures uninterrupted production. Unchecked efficiency can lead to poor order completion and lack of competitiveness.

Flexo printing machine precision directly affects print quality. In turn, print quality impacts the customer’s needs and the business's reputation. The first of these is registration accuracy. A flexo printing machine with high precision should achieve registration error tolerances of 0.1 mm regardless of printing speed. Extreme registration errors can render the printed product useless due to severe misalignment of colors and images. Second, plate mounting precision impacts printing quality. The plate mounting system must fix the flexible plate and align it with the anilox roller and substrate. If the plate is poorly mounted, the ink will be unevenly transferred resulting in distorted images. The third dimension is ink control precision.

It’s important for the anilox roller of a flexo printing machine to have a uniform cell structure since it controls the volume of the ink being used. Equally important is the ink circulation system of the machine since it controls the viscosity and temperature of the ink. Issues such as smudged ink and uneven ink coverage stems from negligence of viscosity and temperature inconsistencies. Not noticing such differential precision indicators when purchasing a flexo printing machine can lead to the rejection of the final product and increased customer dissatisfaction.

Achieving a balance between efficiency and precision requires the consideration of several important elements. The first is the compatibility of the substrate since. Different substrates such as thin films tend to have thick paper and this requires a different configuration of the flexo printing machine. For example a machine meant for plastic films will need a greater control of the tension to help prevent stretching which will affect speed and in turn the precision of print alignment. The second is the level of automation which can increase both efficiency and precision. For example a fully automated flexo printing machine with features like automatic registration adjustment ink viscosity control and defect detection will speed up production while also maintaining consistent print quality. The final factor is after sales support which can guarantee long term performance. The supplier of the flexo printing machine should provide effective maintenance and support with spare parts and technical training.

A highly efficient and precise machine might lose its advantage due to extended downtime caused by inefficient after sales services.

As part of the due diligence, efficiency and precision testing is important. Start with a sample printing test. Give the supplier a target substrate and a print design, and print test to try, and then analyze the machine performance for the claimed printing speed, assess registration accuracy, and evaluate print clarity with special attention to text and pattern sharpness to test clarity. Follow up by assessing setup efficiency. Request the supplier to change a print job variant and time the steps required to replace plates, adjust the anilox roller, and set up the substrate for job change. A flexo printing machine should complete these steps in a time efficient and precise manner. Next, check the quality of the machine key parts: the anilox roller, the plate cylinder, and the tension control. Quality components ensures precision and efficiency for the long run. Last, check for user feedback.

Reach out to other customers to gather feedback about the particular model of the flexo printing machine under consideration to understand its real world use in the aspects of efficiency, precision, and reliability.

By dodging the mistakes below, you will get a flexo printing machine that meets your needs in terms efficiency and precision. First, avoid compromising performance for cost. A low-cost flexo printing machine will likely operate slowly, maintain poor registration and breakdown often costing you more in downtimes and reprints. Second, ignoring future growth potential will cost you. Initially pick a flexo printing machine that will accommodate larger substrates and more color stations to avoid outgrowing your machine. A machine with fixed configurations will limit your production demands and lead to costly replacements. Third, avoid overlooking workflow compatibility. Make sure the flexo printing machine aligns and integrates with your pre press (design software, plate making) and post press (slitting, die cutting) tools. Leaving gaps in your production workflow will create rework and reduce overall operational efficiency. Finally, avoid skipping on-site training. Even a well-designed flexo printing machine will provide poor results if the operators do now know how to adjust the speed, maintain precision, and troubleshoot.

To get the most out of a machine, training is important as it help to optimize its efficiency as well as precision capabilities.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16