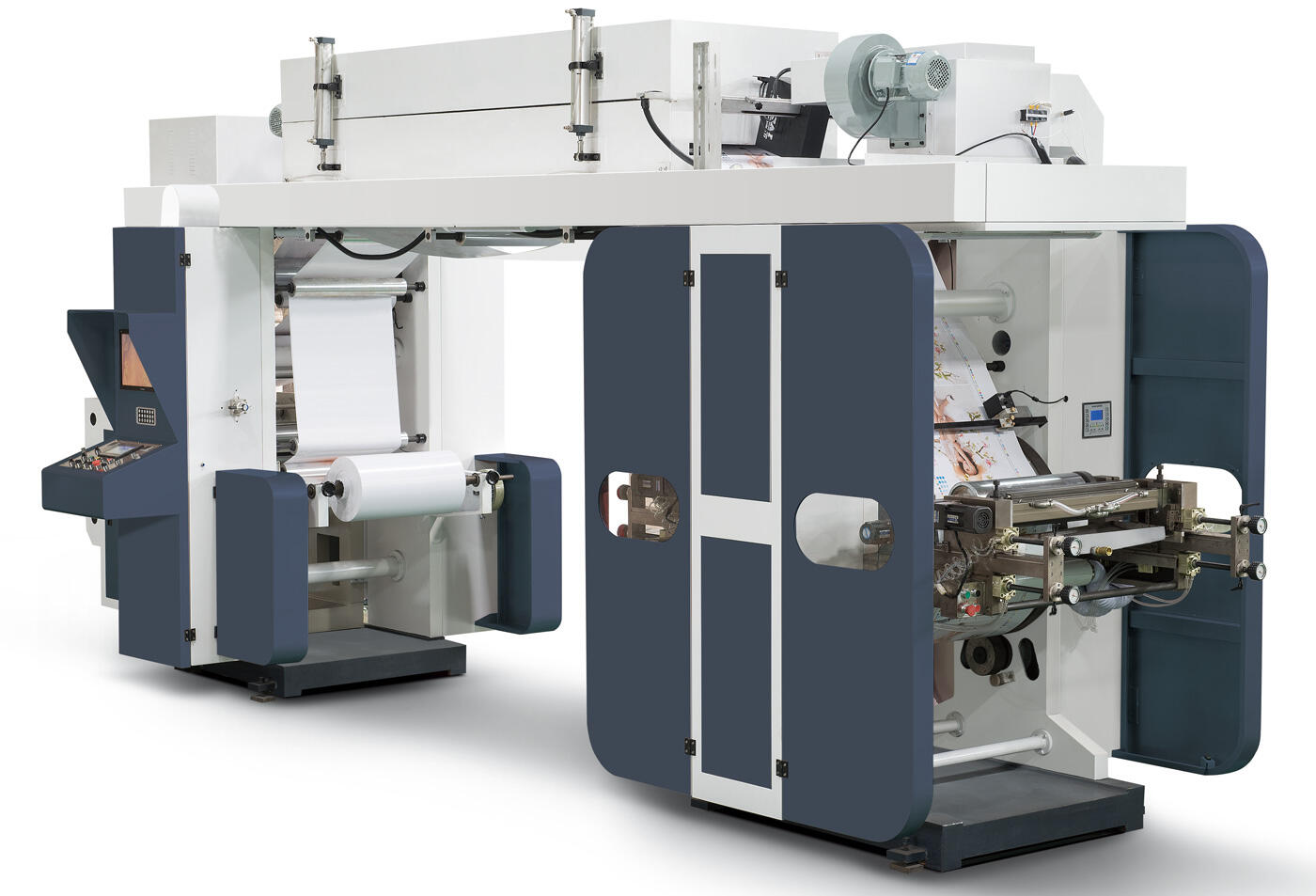

The modern printing industry must determine how flexible a printing machine is with different inks and substrates and how this influences the flexibility of the machine’s production and quality of the output. For the past 20 years, Qiangtuo Machinery has been manufacturing flexo printing machines with a range of products including fully and semi- servo drum satellite models. Apart from the multi- color printing capabilities of these machines, additive manufacturing on key components allows flexibility with various inks and substrates for the industrial grade metals

Qiangtuo Machinery understands the challenges associated with the unique ink drying requirements in flexo printing, taking both water and solvent-based inks into consideration. They utilize maximum drying capabilities with efficiency focused hot air drying features where the air guide plates and metal air-flowing nozzles are precision-designed and engineered using additive manufacturing to drastically improve evaporation rates, eliminate drying detrimental to substrates, and evaporate drying water rapidly. They ensure safe operation with explosion proof ink tanks and system exhaust for solvent-based inks. They utilize structural additive manufacturing for the ink tank seals and metal joints to eliminate ink leakage. Qiangtuo provides customized versions which include ultraviolet (UV) sterilization and ink curing for printed materials, inline with modern flexo printing. The UV lamp holders are designed with precision engineered additive manufacturing and strategic engineering to improve ink curing and ensure complete ink curing with no remnants. Confirming these modern configurations will ensure efficient operation with the required ink.

Substrates such as paper, non-woven fabrics, plastic films, and woven bags exhibit a variety of physical properties, and this demands that flexo printing machines have differing speed ranges and tension control. These two factors must be assessed in order to choose a machine that can accommodate various substrates.

High flexibility in speed control makes Qiangtuo Machinery's flexo printing machines tailored to substrates, for instance, the nonwoven printing machine works at a speed of 150m/min to match the low tension tolerance of non woven fabrics. However, the paper printing machine works at 260m/min due to high efficiency demands. Speed control systems use metal gears and shaft transmission. These systems are precise and low wear allowing for consistent steady adjustment and preventing slippage of the substrate. Control of tension is the other important feature. Qiangtuo's systems sensors have metal cores and are tension made by additive manufacturing. They sense, and dynamically and instantly adjust, substrate tension, for example, during printing of thin plastic films, the system keeps low tension to avoid stretching, and, for thick woven bags the system increases tension to ensure flat feeding. The finishing up speed and control tension to the flexo printing machine characteristics makes it capable of printing a wider and more varied range of substrates.

Color registration is vital to retaining the quality of each print on different materials. If different materials are of different thickness and elasticity, the flexo printing machine may cause registration errors. This is why it is essential to check the machine’s components.

Qiangtuo Machinery’s flexo printing machines are equipped with printed metal advanced flexo printing machine components color registration systems. The satellite flexo printing machine's central drum is composed of high strength metal through additive manufacturing. The drum’s metal construction ensures smooth surfaces and uniform diameters which translates to consistent contact with the material and minor deviations for registration. An example would be the QTFS CI8 8 colors full servo driven central drum flexo printing machine which is capable of switching between different materials and still achieving a color registration precision of ±0.1mm to paper and plastic. The servo motors that control the registration system respond with high torque and speed to metal rotors which are additive manufactured and this enables fast compensating of adjustments for stretching or shrinking materials. This is used to testify to a customer from Qiangtuo that the flexo printing machine provided remarkable color consistency in woven bags and non-woven fabrics and therefore returned due to different shades. This highlights the significance of printing color registration precision on various materials.

A lot of the time, some printing projects require some special ink and different substrates. This will need flexo printing machines with robust customization capabilities. Finding a manufacturer who can provide a tailored and personalized approach for the needs of the machine means the manufacturer will be able to adjust to a one of a kind production requirements.

Qiangtuo Machinery works with one to one machine customization for special ink and substrates. For instance, clients who work with heat sensitive substrates and low temperature curing inks, Qiangtuo is able to modify the drying unit of the machine to a low temperature infrared system. The adjustable unit’s metal brackets are made through additive manufacturing which allows for design adjustments. For thick plastic film where deep ink penetration is needed, Qiangtuo enhances the machine deep ink transfer rollers. They texture the surface of the rollers using additive manufacturing to enhance ink adhesion and transfer. Deep ink transfer rollers have also been modified to work with thick plastic film which needs deep ink penetration. In addition, Qiangtuo provides personalized color configurations like 4 plus 4 colors for printing woven bags to satisfy their multi color requirements. This customization route uses additive manufacturing to quickly provide prototype elements which enhance the printing machine's modification for special applications. By prioritizing customization capabilities, one can be assured the flexo printing machine will be able to best accommodate the special ink and substrates.

A flexo printing machine might need periodic adjustments or maintenance after extended use with different inks or substrates. This is why it is important to do maintenance checks. Also, checking for after-sales support from the manufacturer is important to avoid minor issues.

By offering rapid communication, parts support, and on-site maintenance, Qiangtuo Machinery has made after-sales support as efficient and effective as possible. Qiangtuo offers support for issues such as ink supply system clogging, offering remote support for cleaning and part replacement. The replacement ink nozzles and filters are metal and are 3D printed for durability. Qiangtuo engineers are available for on-site commissioning for adjustments like tension settings for new substrates. A Qiangtuo customer reported to the company after sales support resolved a thin-film remote substrate feeding issue which allowed the customer to take production. Qiangtuo provides a one year warranty with lifetime after sales service on critical components for ink and substrate adaptation. This permits the printer to maintain a high level of adaptability and efficiency.

For time and multi-application use, stability and durability are important qualities for flexo printing machines to balance different inks and substrates over time. Those that are heavily built and are constructed from quality parts will handle various production tasks well.

At Qiangtuo Machinery, component Flexo printing devices use quality metal parts, some of which are additive manufactured. The frameworks of the machines utilize thickened steel plates with additive manufactured reinforcements that stabilize the machine. The QTHA CI8 8 colors high speed semi servo CI flexo printing machine, for instance, performs stable operation at top speed when switching from paper to non woven substrates. The main components, including ink rollers and central drums, are constructed of additive manufactured corrosion resistant metals which are vital for enduring high corrosion in inks, even solvent-based ones, and aiding preservation from corrosion. Qiangtuo performs rigorous di factory testing that includes running the machine with different inks and substrate combinations to proof for extensiveness durability. One customer said that his Qiangtuo flexo printing machine has been running without a hitch for years on many different substrates and has not had any major breakdowns. The focus on durability and stability in machine design means that it could perform reliably over a long time and readily switch different inks and substrates.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16