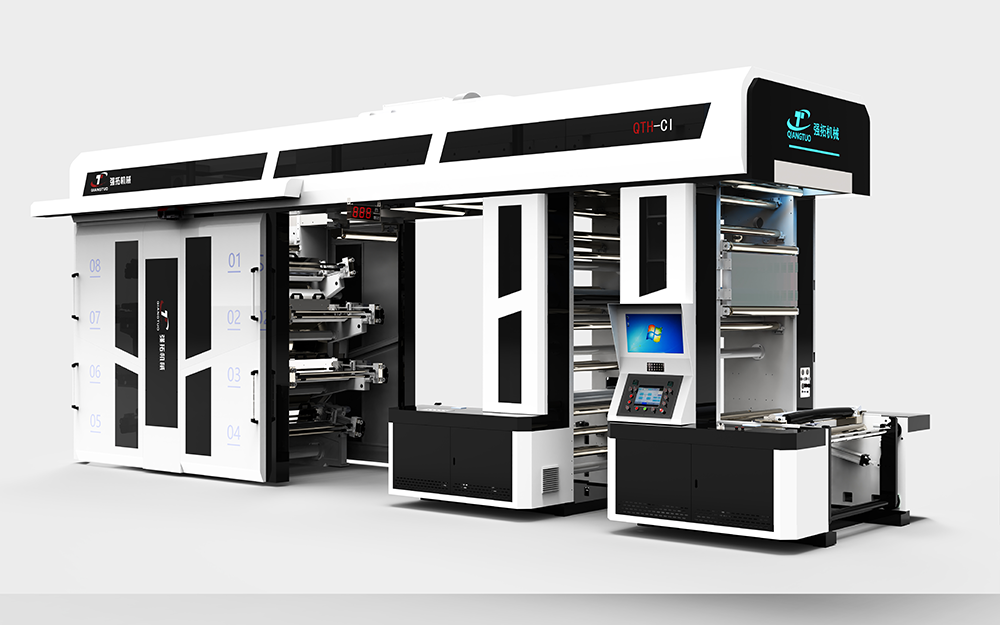

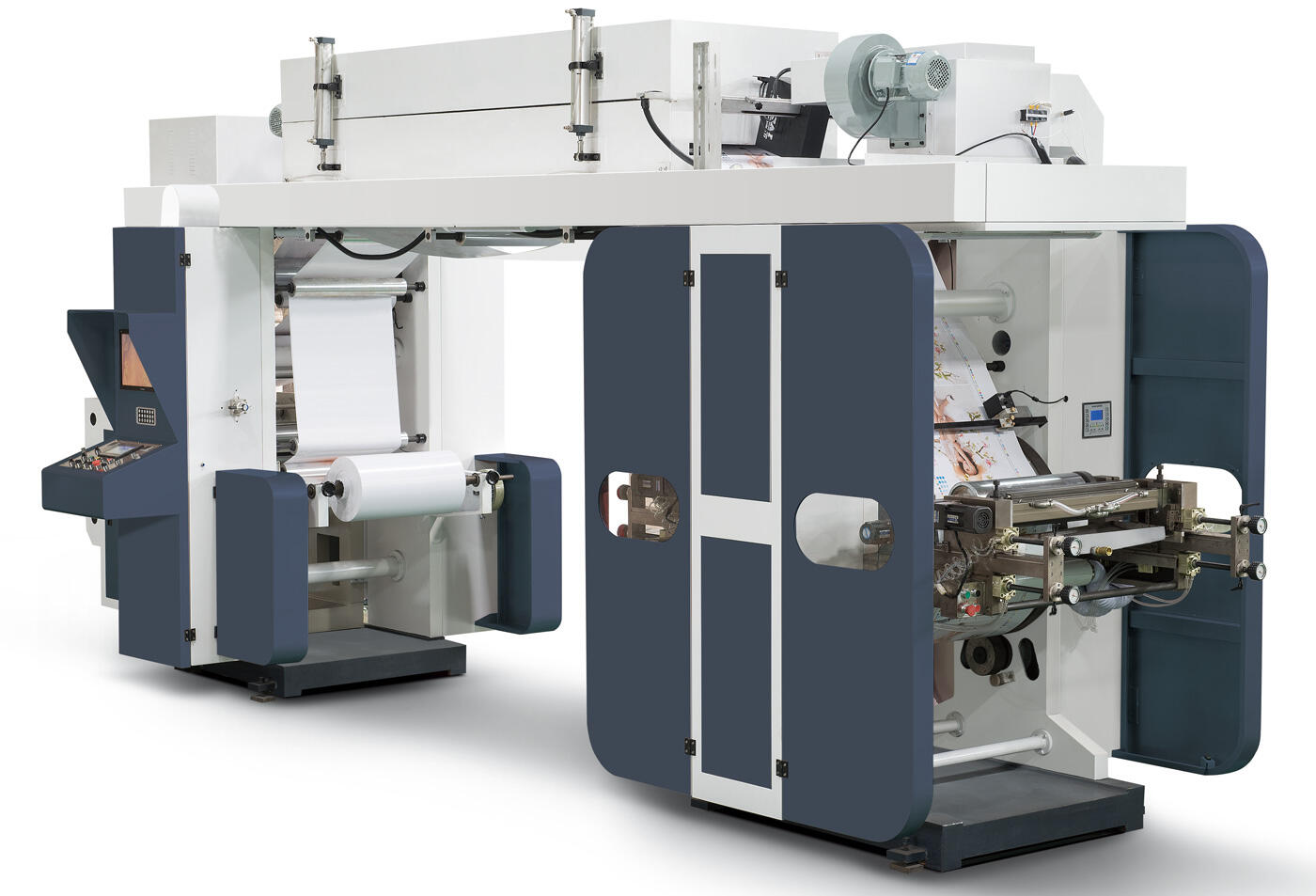

Mylar bags are common in packaging because of their strong barrier properties and durability. Mylar bags help store food, electronics, and everyday items and help keep them safe and undamaged. However, It is common in the packaging industry to experience problems with the printing of mylar bags. This is especially the case with printing logos and designs on mylar bags with curved edges. Common problems involve the printing of designs getting uneven, blurry, or smudged. This has caused problems for packaging industry for a long time. Qiang Tuo Machine is a company in the printing industry that has worked to solve these issues with a high performance printing machine for mylar bags. This machine has earned the trust of customers that required the printing of designs on curved mylar bags to be clear, sharp, and smudge free.

To attain quality printing on crooked mylar bags, it is crucial to keep the bags still and positioned correctly during the printing process. All mylar printing machines from Qiang Tuo Machine come with a precision clamping system. This system does not deform the bags while tightly securing each one. This system comes with soft yet durable clamping jaws, customized to the mylar bags for better deposits. No matter if it is a mildly curved snack bag, or a steeply curved electronic product, the clamping system provides consitent pressure so the bag does not move or fold during printing. Stable positioning is the basis for consistent unifomity of ink, per printing.

Ink jet technology is one of the advantages of Qiang Tuo Machine's mylar bag printing machine for curved surface printing. The machine uses industrial grade , high resolution ink jet heads that can emit small, consistent ink droplets and have an impressive 1200 DPI resolution. This helps to print even the finest details and small texts on curved mylar bags in high definition. The ink is specially crafted for mylar and has quick drying and high adhesion properties. When printing on curved surfaces, the ink jet heads adjust the ink output and the angle of ink spraying in real time based on surface curvature data that is pre loaded into the system. Dynamic on the fly adjustments avoid ink accumulation in concave areas and the ink being deposited in insufficient quantities in convex areas, resulting in consistent and even ink density across the entire curved surface and preventing smudges from slow drying ink.

In order to accommodate the different curved shapes of Mylar bags, Mylar bag printing machines come equipped with smart curvature adjusting technology. The technology consists of high-speed cameras and laser sensors to scan the curved Mylar bags and, before printing, obtain the Mylar bags' curvature radius and smoothness. This information is sent to the machine's central computer, which automatically changes the printing settings, including the distance from the jet of ink to the bag's surface, the speed of the printing bed, and the time it takes for the ink to dry. For example, when printing Mylar bags that have more curve, the machine will go more slowly and dry the ink faster. Machines that print Mylar bags and have this technology installed do not need any of the machine's printing parameters to be adjusted manually to print Mylar bags and, therefore, do these jobs with increased efficiency and quality.

In the printing of mylar bags, especially printing on uneven surfaces, the working conditions play a key role in the printing outcome of the mylar bag and the quality of the print. Environmental factors, such as changes in temperature and humidity, affect the viscosity of the printing ink and the properties of the mylar, causing printing defects such as smudging and poor adhesion. To combat these factors, the mylar bag printing machine manufactured by Qiang Tuo Machine comes equipped with a temperature and humidity controlling system, which keeps the printing area in a perfectly controlled environment of 20~25 degrees centigrade and 45~60% of humidity. This is done in real time with the help of precision air conditioners and dehumidifiers. Proper temperature control ensures that the ink can remain at the right viscosity level so that it can pass through the print head smoothly, and the right level of humidity ensures that the mylar bag surface does not become too dry or too moist so that the ink can adhere properly. All of these factors combined allow the printing machine to provide prints that are clear and smudge free, regardless of the printing surface on the mylar bags.

Qiang Tuo Machines gives extreme importance to each stage of the printing process, and that includes post-printing quality inspections. Every mylar bag printing machine comes with an automated quality inspection system that employs machine vision to scan printed bends. The system is enabled to detect defects such as smudges, blurry patterning, and uneven inking and will mark the products as unqualified. This system helps ensure the quality of the products being shipped and helps manufacturers limit waste and increase efficiency. Additionally, Qiang Tuo Machines offers extensive after sales services including on-site installation, training of operators and maintenance personnel, and 24-hour consulting. The dedicated team of professionals ensure that the customers are able to utilize the mylar bag printing machine in a stable and efficient manner and that the professionals solve any challenges that the customers may face in the production line in an efficient manner.

Qiang Tuo Machine has been in the printing machines industry for a long time and has always emphasized the need for technological advancements and the needs of the customers. The Mylar bag printing machines developed by this company not only print on Mylar bag surfaces, but they do it efficiently and require little to no maintenance. Whether you are a small packagin, workshop, or a large scale production business, Qiang Tuo Machine can give you a Mylar portable printer. The company has a good reputation for providing thoughtful services and high quality products, this is the reason why their services are provided to more places than any other company. Qiang Tuo Machine is a company you can trust to provide you with good Mylar printing machines. A people you can trust for good quality Mylar printing bags.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16