Customization has changed the market for retail, catering, and gifts to include custom made to order paper bags. Such orders require the paper bags to be made with different types of paper and different thicknesses, which makes for higher flexibility demands on the paper printing machine, with not only the ability to ensure quality printing of any design, but, the ability to adjust to different thicknesses of paper, from thin to thick, quite flexibly. As an example, thin, printed bags for the breads may be needed by a bakery, while thick, printed and textured, durable kraft paper bags would be needed for a luxury brand. The ability of the paper printing machine to adjust and flex with differing thicknesses of paper directly determines the ability of companies to satisfy that need from the market and how to create an edge in the market. This flexibility and adaptability in the machine is not just a nice feature to have but rather is a defining feature of the paper printing machine and its order market.

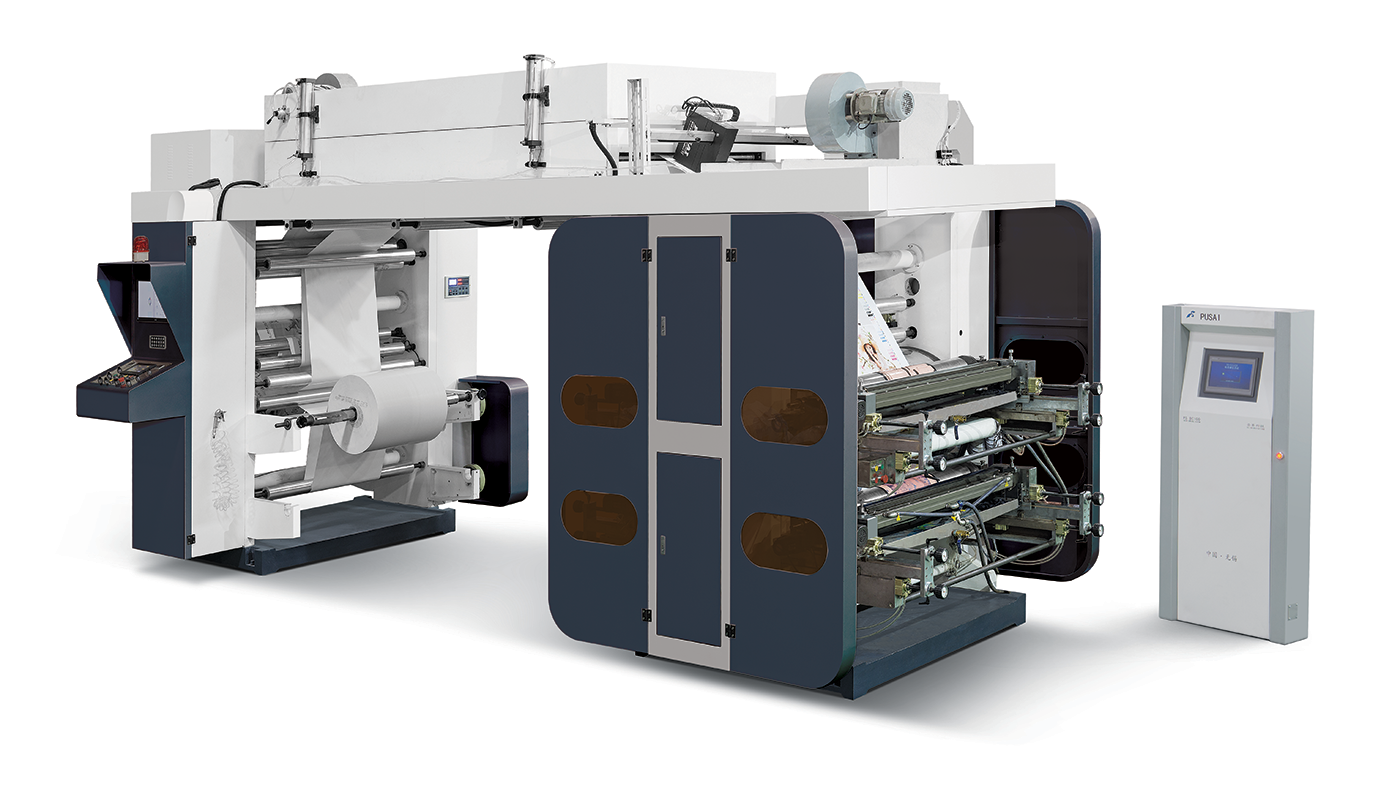

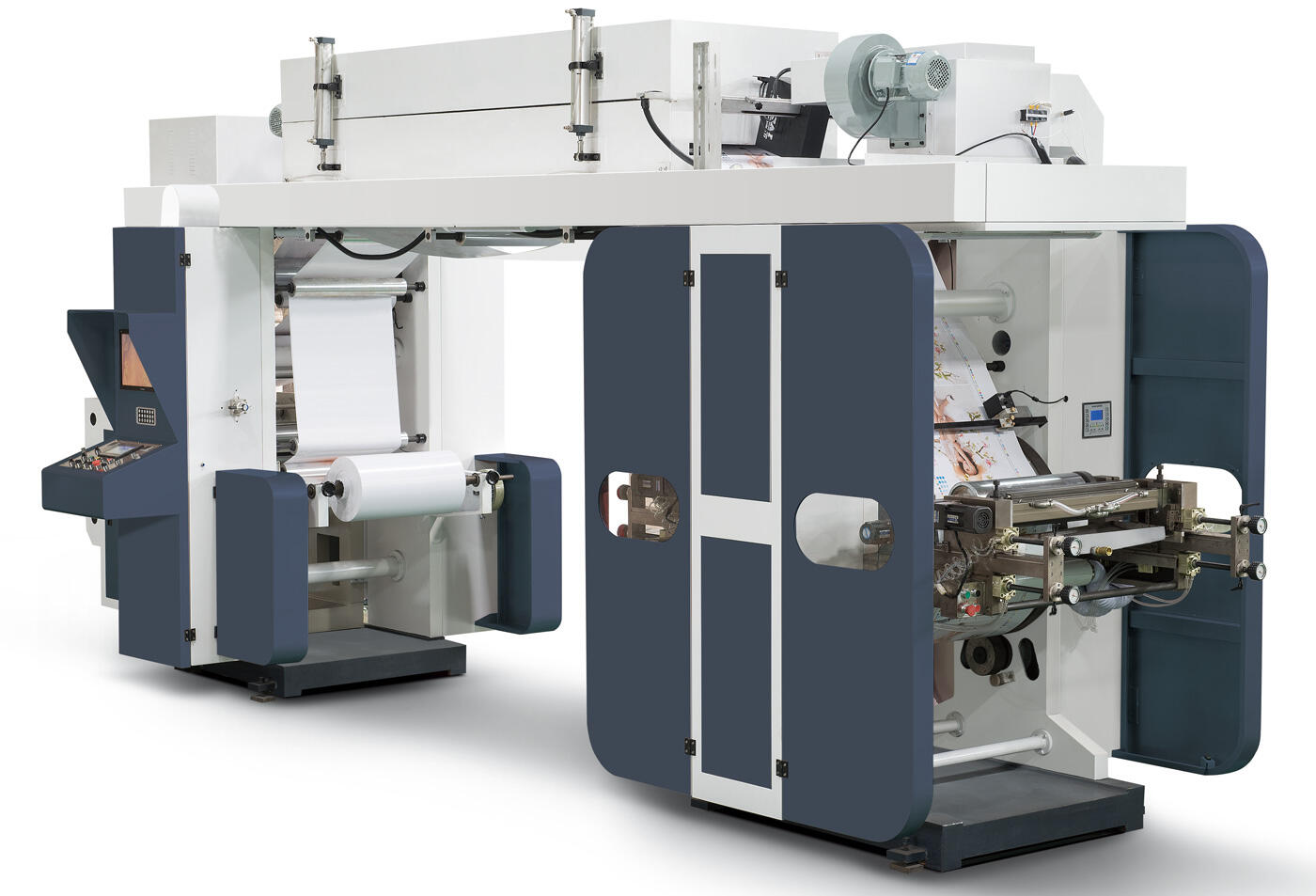

Advanced printing on paper-engravement systems can print on various paper thicknesses because of their advanced pneumatic engraving systems with mechanical setups. These systems have adjustable pressure printing rollers and feeding systems that can be finely adjusted according to paper thickness. Moreover, the operator enters the paper thickness settings on the smart control panel, and the printing machines pressure rollers adjust to ensure smooth paper feeding with no jams or distortion. The feeding systems with elastic tightening designs can also accommodate various paper thicknesses, preventing slippage during printing and ensuring properly aligned patterns. For example, on 80g (thin) paper and 300g (thick) cardboard, the printing machine can adjust parameters in minutes, preventing long downtimes and increasing overall output. This customization of mechanical systems provides a solid basis for cutting and engraving printing machines to meet the wide variety of their market demands.

Intelligent control technology is a major contributor to improving the versatility of the printing paper thickness control technology. Advanced control machinery has the ability to sense the thickness of the paper when it is loaded into the machine. It then sends real time data to the control center where it adjusts the printing velocity, ink volume and pressure. This data control is a better way of eliminating the operational printing control errors and achieves printing quality control consistency for variable thicknesses of paper. For instance, the control sensors will detect a paper thickness increase and print control will result in a slight decrease in the printing velocity while an increase in the ink volume prevention control is inputted to prevent incomplete printing of the design pattern. A small number of control machinery is of a high class technology where control works of memory storage capability. Parameter settings of paper thicknesses in a control sequence are then stored. On subsequent similar orders the control machine can recall and set operational control parameters in an instant. The paper printing machine is more intelligent and precise in control technology.

The ability of the paper printing machine to adjust to different thicknesses of paper is due to the configuration of the ink and the printing process. Different thicknesses of paper have different water absorption and smoothness, so the paper printing machine has to change the ink and printing process. When printing on thinner paper, the paper printing machine should use quick drying ink to avoid absorption and cause the pattern to bleed. During the printing of thick cardboard that has a rough surface, a thicker ink layer has to be used along with a more viscous ink to make sure the pattern is strongly bonded to the paper. Also, the type of printing process the paper printing machine uses, like offset printing, flexographic printing, or digital printing also has to change with the thickness of the paper. Of the three options, flexographic printing is more suited to thicker paper but offset printing is better to use with thinner paper to keep delicate patterns. A paper printing machine that can seamlessly adjust the type of ink and printing techniques according to the paper thickness is more likely to satisfy the specialized requirements for custom jobs.

Multiple instances demonstrate how the functioning of paper printing machines can deal with different paper thicknesses and perform customized orders at an impressive rate. An example of this is a packaging printing company in Guangzhou that received an order from a fully integrated shopping mall requiring the printing of ten different styles of paper bags, with paper weights ranging from 100g to 350g. The company utilized an automated IT paper printing machine with an automated thickness adjustment feature. After adjusting to some pre-set values stored in the computers, the machine was able to quickly adjust to different thickness levels. The printed paper bags had distinct, consistent perfect color prints with no defects, paper jams, or pattern misalignments. Another example is that of a gift box customization company that employs a paper printing machine to decorate both thin tissue paper and thick base paper. The company was able to secure more orders of customized fotos since the machines printing and pressure adjustment systems on both paper types were able to meet the standards of the desired prints. Both examples employed reflect the versatility of thickness in paper printing machines in modern engineering.

How to Select a Printing Machine that Fits Your Needs

Understanding Your Business Needs

While enterprises understand business needs to pick a printing machine to accommodate different orders that come with different paper thicknesses. Consider a couple of fundamentals. First, with a potential printing machine, examine its mechanical range adjustments to confirm if it can accommodate the consistency of paper thicknesses needed for an enterprise's frequent orders. Second, inspect the paper printing machine's intelligent adjustment level, such as whether it has an automated paper thickness detection to help enhance production efficiency, as well as memory functions for an optimization of its operations. Third, understand the printing machines compatibility with different types of ink, as well as with the printing methods to ensure quality finishes for highly differentiated paper.

Besides the mechanical printing machine adjustment scope and its compatibility with its most common and other added value requirement orders, the after purchase concern is also important. The customer service of the paper printing machine providers can be a valuable asset as their added value lies in their ability to offer immediate technical interventions to enterprises regarding the challenges current and potential users will face with different thicknesses. This will undoubtedly be an important investment enterprises can make to acquire a paper printing machine, as it will avail enterprises investment the ability to diversify and enhance core business competitiveness.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16