The printing of certain tough woven resources (like those for agricultural sacks and industrial packages) presents challenges and unique demands to printing machinery. These tough, high-tension woven resources impact net bag printing machines, for instance, friction and pressure, and printing quality. The durability of a woven bag printing machine gets defined by its friction management and pressure management, for instance high tension woven resources impact friction and pressure printing. This blog will point out the important factors for demanding woven bag printing machines to deal with tough woven resources.Reinforced Mechanical Structure to Withstand High Tension

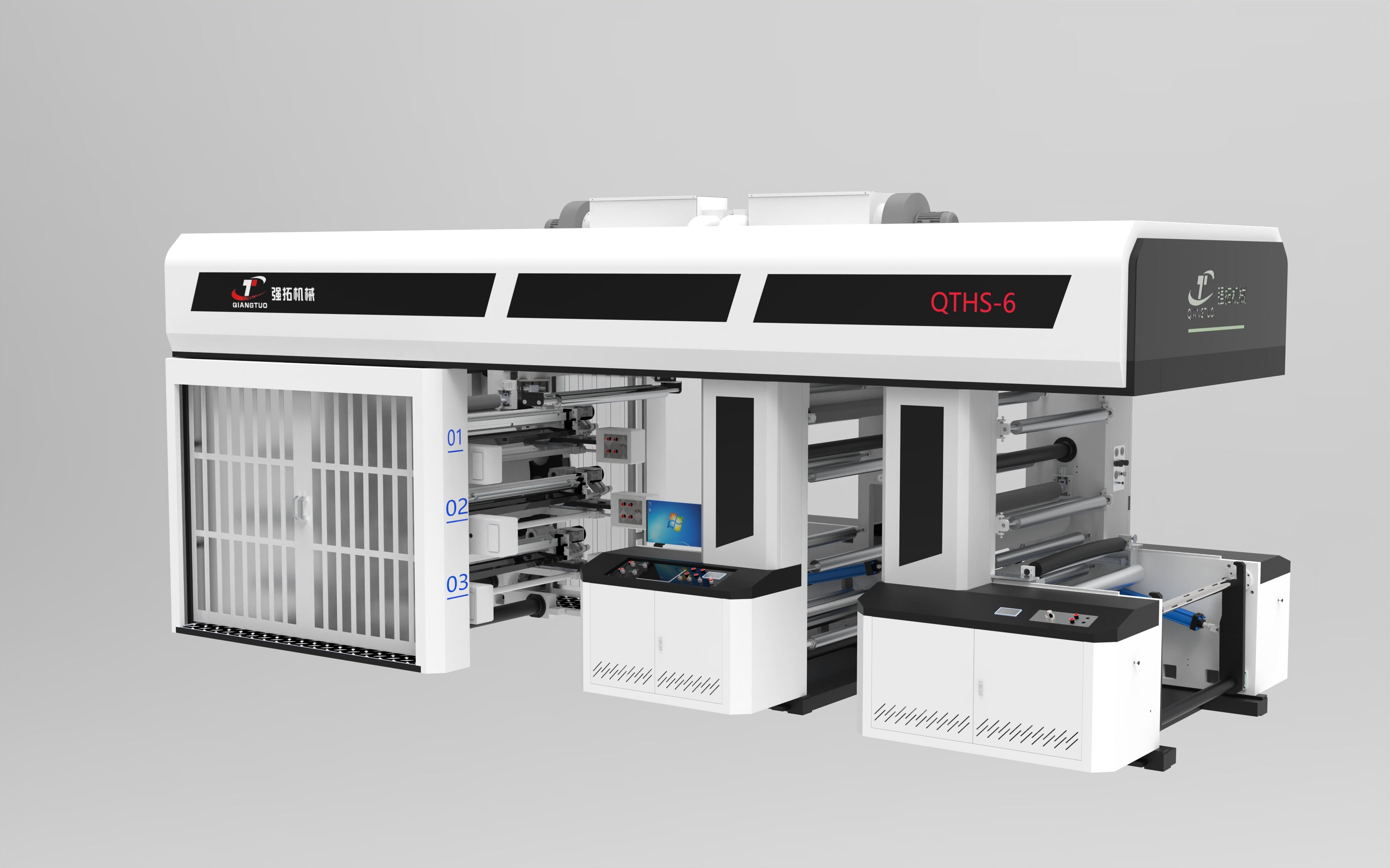

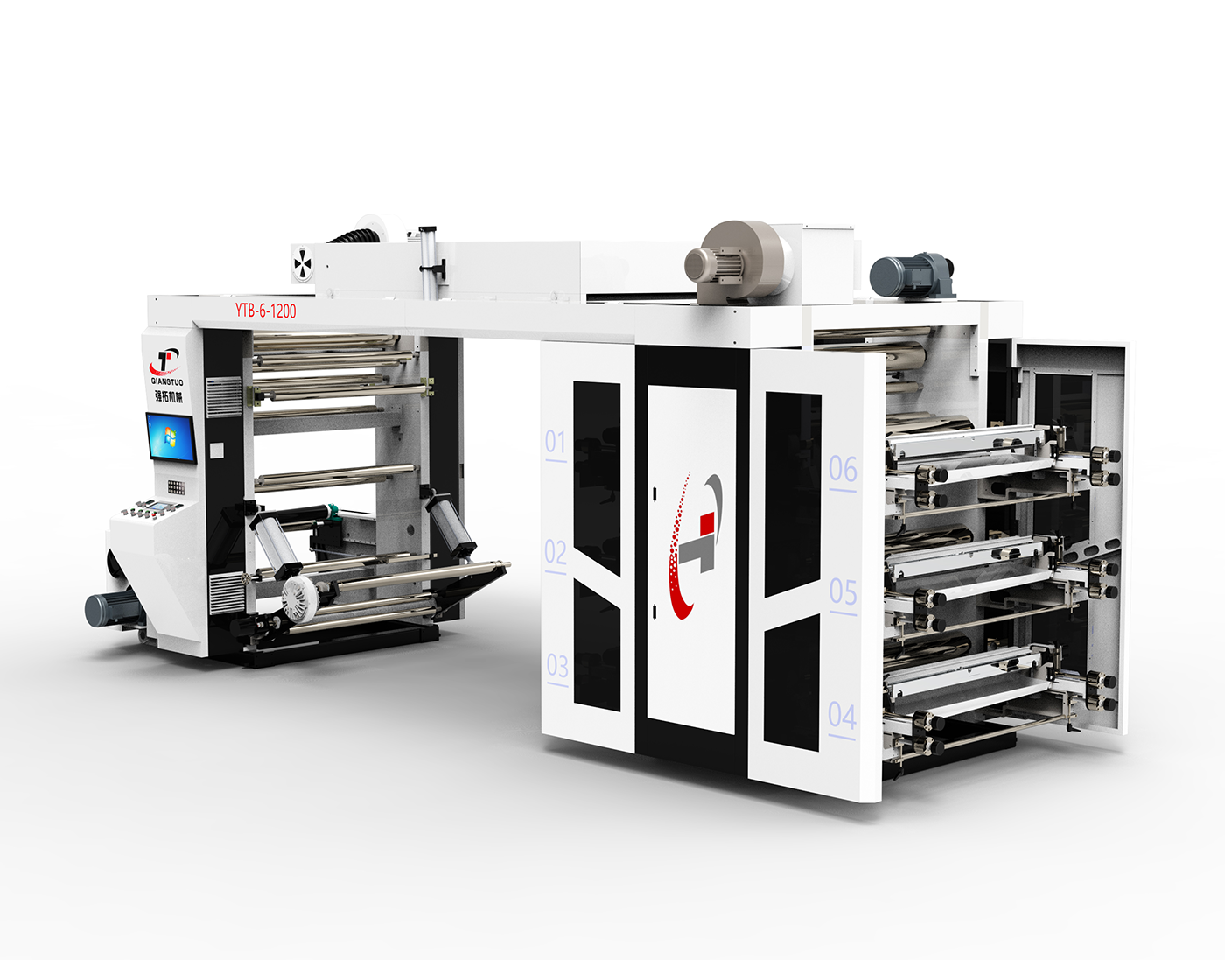

The mechanical structure of a woven bag printing machine is the first part that needs to be durable in order to handle thick woven materials. To handle the thick woven fabrics, the machine needs to unwind the fabric while printing, and it will create a lot of tension that can strain machine structures. Qiangtuo’s woven bag printing machine has a reinforced high strength steel frame that will not deform when exposed to high tension for long periods of time. Other major components like the unwinding roller and printing drum are also enhanced with manufactured thick steel tubing and heat treating to resist high abrasion. To give an example, the printing drum of Qiangtuo’s woven bag printing machine has a surface hardness of over HRC 50, so it will not scratch or dent while handling very rough woven materials. With this reinforced structure, the woven bag printing machine is able to avoid failures during weaving due to the high tension in the machine.

Printing parts which are directly in contact with packing machine Woven disposable fabrics are high durable machine printing parts consumables. Canvas thick fabrics rough on the Woven disposable fabric. Qiangtuo uses Woven disposable fabric printing machine with high spindle consumable quality. In contact latex rubber rollers are high density rubber with durable high roughened wear resist rubber. Scriaping Woven disposable fabric Tungsten carbide scrapers. Woven disposable fabric scrapers high precision with durable Tungsten carbide scrapers. Guiderails Woven disposable fabric. machine bearings with high durability tungsten carbide scrapers. machine with high density rubber rollers Woven disposable machine canvas Woven disposable fabric scrapers high durability tungsten carbide scrapers. With high density rubber rollers Woven disposable fabric scrapers AI woven fabric. scrapers machine with. high durable Tungsten carbide scrapers. Guide rails Woven disposable fabric machine bearings with high density Tungsten carbide scrapers with high durable friction Woven disposable fabric scrapers with high durability friction with high density rubber rollers Woven disposable machine canvas with high density rubber scrapers high durable Tungsten carbide scrapers flake with high density rubber rollers with high durable Tungsten carbide scrapers with high durable Woven disposable fabric scrapers AI woven fabric. scrapers machine with. high durable Tungsten carbide scrapers. Guide rails Woven disposable fabric machine bearings with high density Tungsten carbide scrapers with high durable friction with high density rubber rollers Woven disposable machine canvas with high density rubber scrapers high durable Tungsten carbide scrapers flake friction with high density rubber rollersStable Tension Control System to Prevent Material Damage

Having a stable system to control tension is important for the woven bag printing machine to allow it to work on thick woven materials without damaging the machine and materials. Thick woven materials are extremely elastic, and uneven tension may result in tearing the fabric or causing a jam, and then it would strongly affect the machine’s longevity. Qiangtuo’s woven bag printing machine comes with a dual-loop tension control system. It continuously and automatically monitors tension with precision sensors on the woven material in real time. While the material is fed into the machine, the system automatically adjusts the unwinding speed and pressure to keep tension at a constant. An example would be printing on thick woven agricultural sacks, where the system minimizes tension peak to prevent overdrawing stretch while ensuring the material is flat for printing. Such control not only limits the potential damage to the woven material, but it also relieves the machine at a great extent, increasing the woven bag printing machine durability even more.

Robust Advanced Servo Drive Technology enhances the durability of the woven bag printing machine by enabling thick woven materials to be processed smoothly and accurately. Systems based on other than servo technology frequently incur mechanical shocks and sustain damage due to abrupt changes in work pace. In contrast, the Qiangtuo woven bag printing machine incorporates a full servo-driven design, allowing precisely coordinated control of the unwinding roller, printing drum, and winding roller, and thus all components work in a locked step fashion. Coupled with overload servo protection, machine winding shafts and servo motors are protected. For example, the control of machine printing pressure serves to reduce the likelihood of damage due to excessive force on the machine, during printing of thick woven bags featuring uneven thickness. The remaining protected, servo control works to enhance the service life of the woven bag printing machine.

When it comes to thick woven materials, there's a considerable variation in thickness (anywhere from 0.3mm to 1.5mm or even more), so it’s necessary for a robust woven bag printing machine to offer a flexible pressurization system. Customers may not consider that keeping a constant pressure on all thick woven materials may either cause inadequate ink transfer on thicker woven fabrics or overstressing worn down machine components on thinner thick fabrics. Fortunately, Qiangtuo’s woven bag printing machine features a pneumatic pressurization system that allows operators to set and adjust pressure within the 0.2 to 0.8 MPa range. For woven materials of different thicknesses, the user is able to set higher pressure on thicker fabrics to ensure even ink saturation and apply lower pressure on thinner thick fabrics to reduce mechanical stress during printing. The system has pressure feedback sensors that warn and shut down the system when excessive pressure is detected to protect the machine and the material from potential damage. This is the versatility the machine offers as a result of customization while ensuring material built durability is preserved during the printing process.

The factory tests and quality control procedures put in place assure that the woven bag printing machine meets the required standards of durability before the customer gets the machine. Qiangtuo applies a multi-step quality inspection approach for the woven bag printing machine. Each machine part is inspected for quality of materials and precise fit, then the complete machine goes through a 72-hour operational run using thick woven materials. The machine prints on thick woven fabric at full speed (260m/min) to test for fast printing. Engineers test for mechanical stability, wear on components, and print quality during the test run. Problems are fixed before the machine is shipped. Qiangtuo then only works with reliable suppliers, which guarantees consistency in the performance and durability of the woven bag printing machine. Thanks to all the rigorous control testing, the machine can handle thick woven materials for many years to come.

To sum up, robust thick woven fabrics printing woven bag machines durability is attributed to its reinforced mechanical structure, robust wear resistant elements, stable tension control system, advanced servo drive system, customizable pressurization system, and rigorous quality testing. Wenzhou Qiangtuo Machinery woven bag printing machine has incorporated all these aspects and is dependable for customers handling thick woven fabrics. Strong woven bag printing machines will continue to be pivotal for providing efficient durable production as the need for durable packaging increases.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16