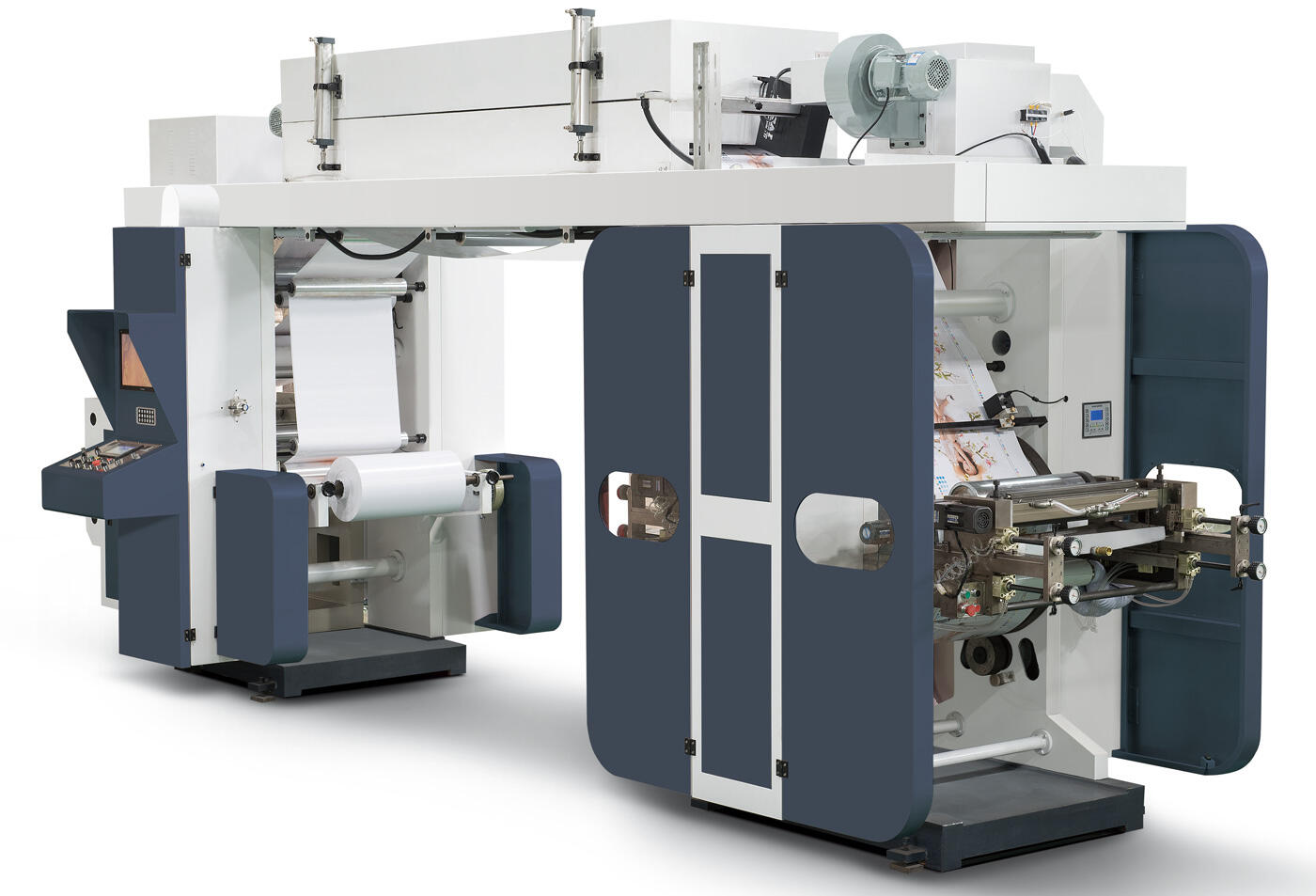

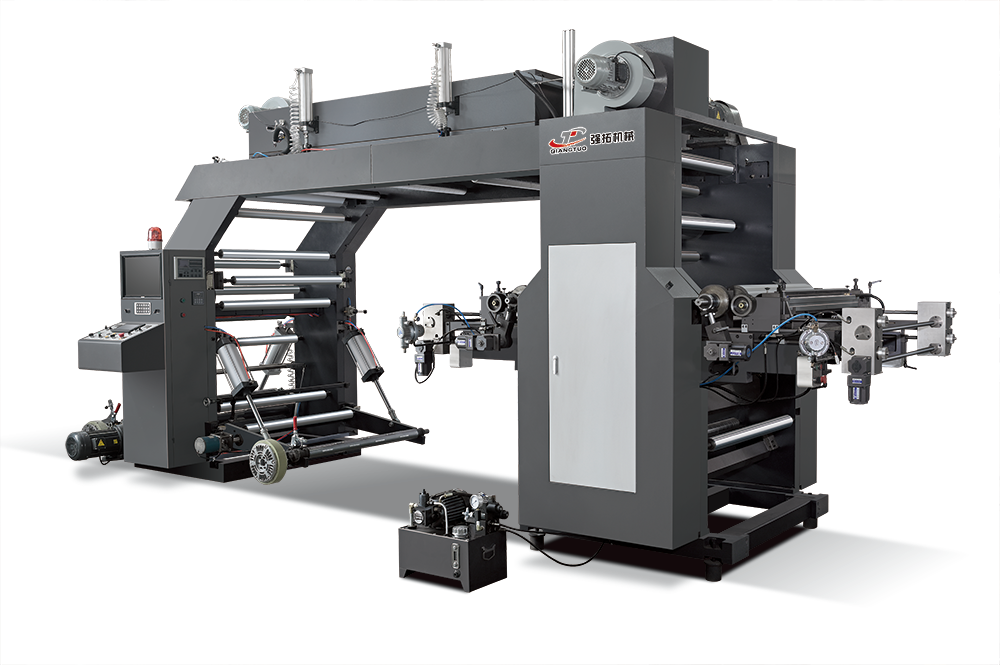

The paper cup production industry has to deal with an issue of ink bleeding on the substrates of printed paper cups during production. This issue negatively impacts the quality of the products and tarnishes the reputation of the businesses producing the cups. Qiangtuo, a company specializing in the production of flexographic printing machines for over 20 years, has engineered a machine specifically designed to print paper cups of exceptional quality without the bleeding of ink onto the substrates. Many of Qiangtuo's customers are printers of paper cups and thus they are aware of the industry struggles and appreciate how Qiangtuo's machines have solved the issue of ink bleeding onto substrates. This blog analyzes and presents the reason for Qiangtuo's success in servicing customers from all corners of the globe in the field of printed paper cups.

Qiangtuo has state-of-the-art technologies in paper cup printing machines that feature no ink bleed with satellite-type micro ink control technologies that utilize intelligent ink delivery to control viscosity with respect to each paper cup substrate. Each paper substrate used to make paper cups has different moisture absorption rates. Qiangtuo’s paper cup printing machines have mechanisms that respond to different paper moisture metrics to deliver the correct ink volume required. Controlled with precision to cut bleed, the micro adjustable scraper blades on the printing machines eliminate the risk of applying excessive ink with the promise of greater control to respond to any requests to alter the thickness of the ink layer. These technologies control the ink adherence with a guarantee in precision that paper no longer absorbs excessive amounts of ink to a point of cupping.

To avoid ink bleeding, compatibility between ink and substrate plays a key role and Qiangtuo took this into consideration with their paper cup printing machine which accepts quality water based inks which are eco friendly and have a great adhesion level to paper cup materials. Providing professional recommendations on ink selection, Qiangtuo's technical team assists customers in making matching substrate paper to their inks. For paper cups, coated or uncoated, the paper cup printing machine integrates ideally with matching ink to reduce the risk of bleeding. The ink curing system on the machine also speeds up the drying of the ink post printing so it doesn't migrate on the substrate surface.

Trouble with getting bleed-overs while printing on cups? It cannot be more frustrating than that since excessive ink bleed ruins the whole print design. Thankfully, Qiangtuo's cup printing machine is focused on anti-bleed technology as a core design element. Their unique method design developed a more seamless printing technology while detecting precise wheel movements that sync perfectly with every cup making sure the ink is dead on without getting excessive bleed. The electro-servo drive system allows control over 4 printing colors dead on as to not overlap i.e. where the bleed usually starts. The cup printing machine ensures that the printed cup is evenly filled with design so that there is no excessive ink bleed. Qiangtuo’s system and design manage to accomplish high speed printing while maintaining optimal bleed control, flying up to 260m/min.

Bleed-overs and control there-off, presents with challenges never the less, the better the handling the better the anti-bleed. Qiangtuo gets the handling right and is best on the market. Their unique design ensures that the substrate material is evenly and cautiously handled presenting perfect control while never loosing glue integrity, moisture or is damaged. Specialized roller guides keep the substrate stream flat over and in constant control to eliminate even the slightest material fold or ripple that would blank a layer underneath or cause bleed over rectangle printing. Qiangtuo are the best on the market offering printed cups with perfect color control along with 100% no substrate fold or ripple origination from the printer. Substrate tension also is regulated to material thickness with optimal results.

Continuous quality assurance improvements guarantee that each paper cup printing machine has superior anti-bleeding capabilities. Qiangtuo collects and implements feedback on each machine's anti-bleeding capabilities from regular calibrating adjustments and machine performance over time. Each machine has corrections done to the control ink pressure and registration systems after every machine calibration. Simulations of ink bleeding on specific paper substrates flawless printing across diverse substrates is the benchmark that each machine has to meet. Qiangtuo has proven bleeding control performance feedback and calibrating mechanisms. Continuous adjustments and calibrations guarantee operational excellence and bleeding control capacity. Every machine has proven control capacity and performance feedback.

Realizing that each paper cup has differentiated printing and paper requirements Qiangtuo prints machine Qiangtuo prints paper cup machinery offers tailored systems for every paper cup printing machine. Adjustments to a printers ink supply systems pressure and drying time after printing a design are variable to each printing. Each paper cup machine has a one on one tailored service scoped to unique production requirements. Customization ensures that targeted bleeding control is adapted by the machines. Customization simplicity ensures that production requirements are met. Adjustments to Qiangtuo ink control ensure machines control bleeding tailored to complex patterns.

To sum up, Qiangtuo's paper printing machines pinpoint the factors that cause ink bleeding on paper cup substrates and offer effective solutions. With a bespoke management system, the machines control and process substrates through a series of regimented and controlled steps while keeping the ink compatibility and machine registration at the highest levels of precision. From manufacturing flexographic printing machines for 20 years, Qiangtuo has experience with customer service, and has refined and perfected a robust technological and interdisciplinary solution toward the seamless automation of every component of the paper cup printing process. Paper cup manufacturers can depend on Qiangtuo for consistent and dependable printing solutions. Qiangtuo's paper printing machines have pioneered the industry for providing high quality and reliable solutions, and that is the reason their paper printing machines have become industry standards.

Hot News

Hot News2025-06-14

2025-06-15

2025-06-16